Company Profile

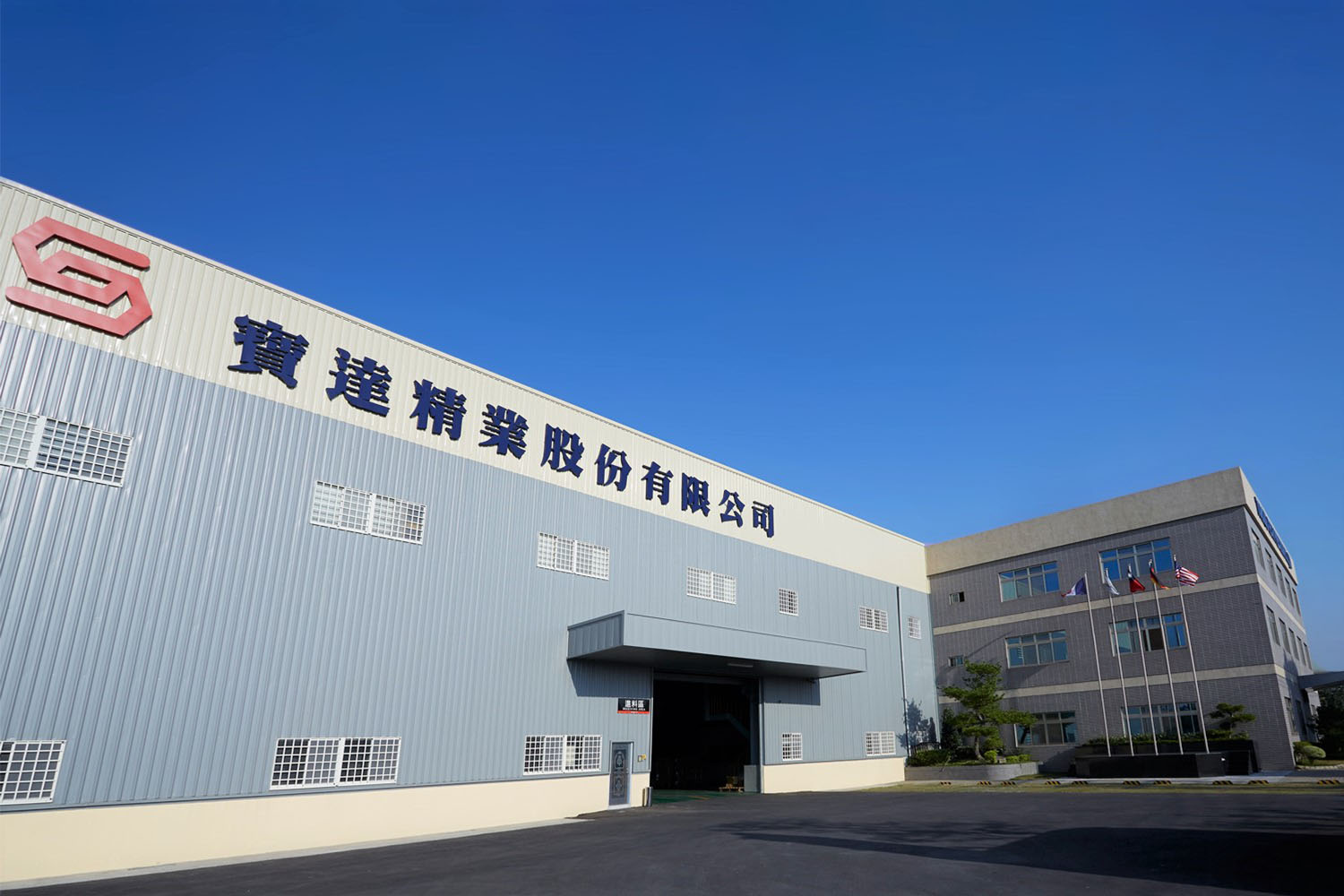

Torque-Tech, the leading torque wrench manufacturer,

was established since of year 2000 and is the leading B2B torque wrench and torque tools supplier in Taiwan. With offering the wide range of products in hand torque tools, we've earned the high reputation from our global customers.

Through continuous investment in the product innovation and technology integration, as well as introducing the QC system, measuring instruments and calibration certificates, it has promoted our competence and increased our visibility in the industry.

100% Made in Taiwan

All our products made and manufacturing services offered are in Taiwan. This is not only the company policy, but also our quality commitment to our customers.

Customer Service

Upholding the spirit of putting our customers first, we will keep focusing on the persistent quest for quality products and take customers' satisfaction as our ultimate goal as principles.

Torque-Tech's sales team provides instant technical and business support to our customers, such as market information, product analysis, purchasing plan suggestion….etc. For the product repair service, we also provide the maintenance SOP and training course to meet the client's needs.

Expansion Plan

Torque-Tech is estimated to make the expansion in year 2024, in order to increase the capacity and satisfy the customer's needs. The land area will be extended from current 6500㎡ to 13,000㎡.

Vision

We will keep providing quality torque tools products to the customers in the field of aerospace, manufacturing, transportation, wind power, and energy generation. We are confident to achieve the next new milestone, based on our experienced staff, excellent customers, dedicated service, and potential growth momentum.